The ocean is home to some very hostile environments: extreme temperatures (from relatively tropical at the surface to near freezing at extreme depths), immense subsea pressures, and corrosive elements at play throughout the water column. And that’s not to mention the destructive forces associated with tides, currents, waves, and other weather patterns that govern so much of the climatic volatility.

Although tech-led research enables us to model and monitor many of these variables, the day-to-day working conditions for professionals in the ocean sector are always hard to predict. The only certainty, especially as sector-wide ambitions lure us to explore new depths in remote waters, is that mitigating risk—to both personnel and equipment—must remain an organizational priority.

Okeanus was created in 2013 to help serve and protect the interests of ocean explorers and offshore developers by designing and manufacturing deck handling systems to withstand the rigors of working in the harshest regions of the planet, and to any depth. Today, the company boasts a best-in-class portfolio of A-Frames, winches, LARS, and other innovative deck solutions. Whatever the mission, Okeanus has the deployment and retrieval equipment to safely and efficiently handle your asset.

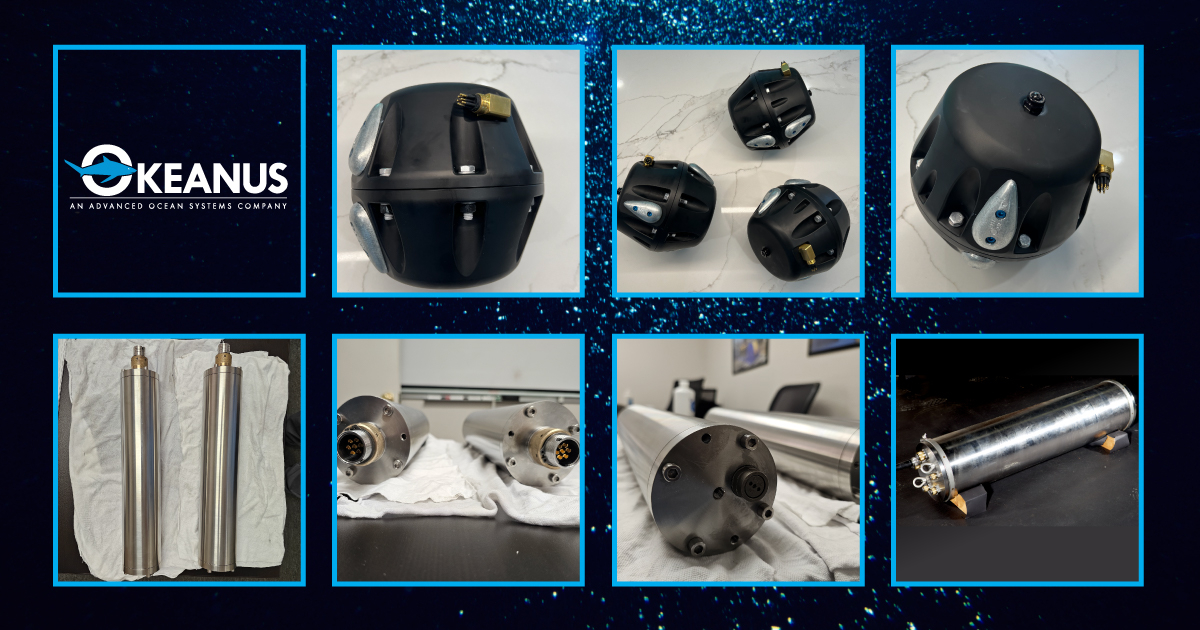

While best known for its heavy-load handling systems, Okeanus also collaborates with customers worldwide to design ocean-proof housings that safeguard critical electronic components. These housings are dry pressure vessels designed to secure sensitive equipment from the extreme pressures and corrosive nature of subsea environments.

They are instrumental for a range of offshore applications across various industries, ensuring that electronics, control systems, and sensors remain isolated and fully functional for the prescribed length of deployment. This includes as part of the integration of a payload or sensor suite into an uncrewed vehicle, like an ROV or AUV, engineered to dive impressive depths repeatedly.

As with all equipment destined for exposure to marine elements, the choice of materials is all important. This consideration, alongside the housing’s shape and dimensions, will always depend on the target use of the equipment it is protecting. To meet the growing demand for custom-built pressure vessels while maintaining full control of the design-build process, the company has invested in new machining capability to bring the vast majority of fabrication projects in-house.

Typically, customers provide the details of their internal electronics and the dimensional requirements, but to date, Okeanus has produced housings of all types and sizes. When appropriate, the team partners with the client from as early in the briefing process as possible to help make sure they can design around all possible requirements. Cylindrical housings tend to be the most common, but spherical and odd shaped ones are also increasingly sold.

Materials used include various aluminum types, titanium, stainless, and even plastic for shallow water assignments. Okeanus routinely builds housings depth rated to 6,000 m but can manufacture for deployment to any depth, including full ocean depth.

Okeanus’ titanium housings are preferred for deep-sea activities due to its weight-strength ratio and corrosion resistance. The density of titanium is approximately 4.5g/cm³, about 60% of that of steel. This fundamentally means that a titanium pressure vessel, under the same conditions, will be lighter and last longer, and so more advantageous for both logistics and deep-sea deployment.

Titanium can withstand extraordinary hydrostatic pressure, which is distributed evenly to ensure that there is no deformation or rupture to the structure, regardless of whether spherical or cylindrical in shape. As a non-toxic and non-magnetic material, it is not affected by underwater magnetic fields. It outperforms other non-corrosive alloys on all counts.

255 Equity Blvd.

Houma, LA 70360, USA

+1 985.346.4666

11989-A FM 529

Houston, TX 77041, USA

+1 713.460.1400