In November, The Metals Company (TMC) announced the successful retrieval of 3,000 tonnes of potato-size polymetallic nodules from seafloor depths of over 4,000 meters in the Pacific Ocean’s Clarion Clipperton Zone (CCZ). In total, over 4,500 tonnes were harvested by a custom Allseas-designed collector vehicle, of which 1,500 tonnes were purposely left on the seafloor, with the remainder being transported to the deck of the recently outfitted Hidden Gem via a 4.3-km riser pipe system.

For many, even the most seasoned of ocean professionals, deep-sea mining remains a cloudy prospect. Opinion and conjecture tend to dominate the headlines. Robust scientific analysis and technical transparency less so. However, for a certain breed of Deepwater technician—like those who comprise the expert subsea engineering and fabrication team at Okeanus—the successful completion of TMC’s full scale-system demonstration in the CCZ—the first since the late 1970s—is more than just an historic milestone.

This profound accomplishment crowns decades of technical speculation and debate surrounding the most effective and responsible way to mine the staggering volumes of these naturally occurring rock concretions, rich in increasingly scarce metals such as cobalt, copper, and nickel, among other rare earth ores. (Accumulations vary but even conservative estimates suggest a potential of 15 – 20 kilograms of nodules per square meter.)

The goal for developers as they field these sophisticated collector systems is to establish and validate a safe, secure, and ecologically sound means of gathering and processing a yield of nodules sufficient enough to create not only a new and sustainable mining industry, but one able to supply today’s society with a steady and reliable source of the much-needed metals required to build out and fulfil the infrastructural needs of tomorrow—a future reliant on mass electrification supported by next-generation battery manufacturing and towering renewable energy infrastructure—today. Stakeholders maintain that offshore mining activities will also help expand our collective understanding of deep-sea environments through a program of ongoing environmental monitoring.

Whether the seabed mining industry transitions from the current exploration phase to full commercial exploitation is now more a question of public policy and regulation—the purview of the International Seabed Authority (ISA) and its member states—as opposed to technical capacity. After all, much of the equipment used during TMC’s pilot test isn’t all that dissimilar to what was used by the mining consortiums in the late 1970s, one of which, Ocean Management Inc. (OMI), had now-retired SOSI/Okeanus founder Ted Brockett on deck to process the ice-cold nodules. Modified most certainly, but most of the critical assets—such as vessels and riser pipes—are borrowed straight out of the long-established offshore oil and gas E&P toolkit.

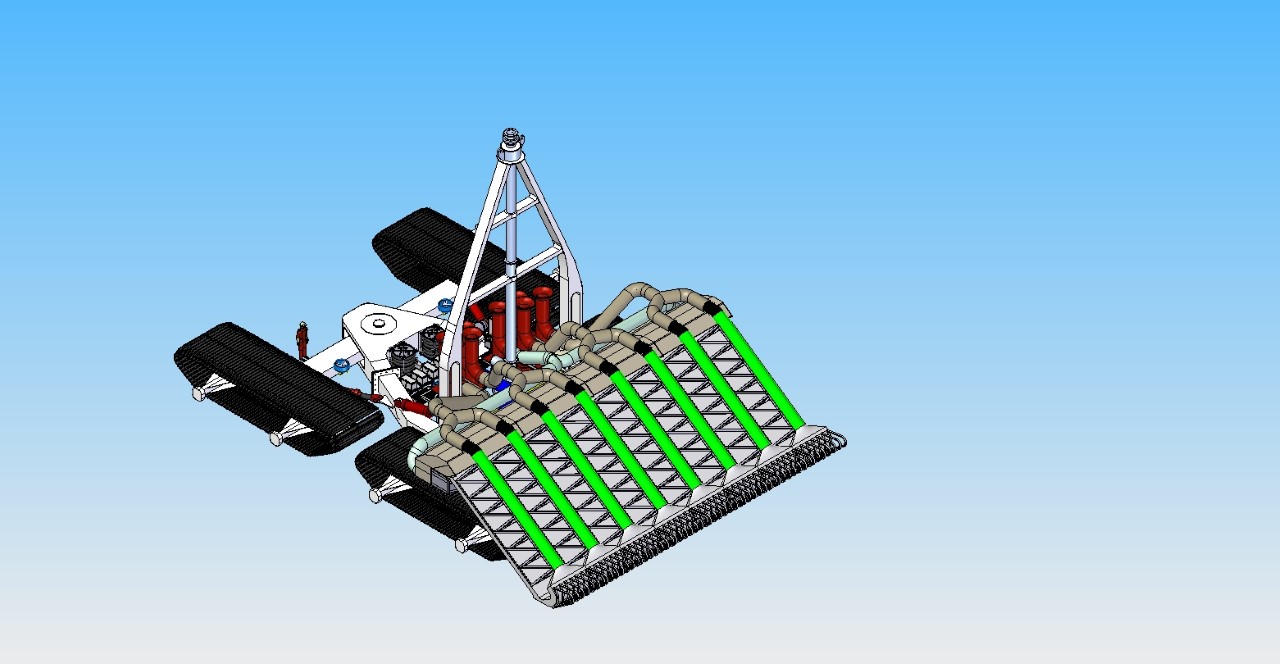

But not the collector vehicles; they truly represent the pinnacle of present-day subsea engineering. While current proposals do vary—for example, TMC and Allseas advocate the efficacy of a trencher-like vehicle, while others, including Impossible Metals (previously Impossible Mining), proffer a more exacting approach to nodule selection by deploying AUV swarms—designing equipment to operate reliably and efficiently at depths of up to 6,000 meters poses unique challenges. Notwithstanding the many technical innovations that our twenty-first century ingenuity has brought to underwater exploration, working at these depths isn’t easy.

TMC’s haul of 3,000 tonnes of polymetallic nodules aboard Allseas Hidden Gem. (Photo credit: TMC)

As an example, despite a very professional and transparent approach involving independent environmental monitoring and state-of-the-art technology, Global Sea Mineral Resources nv (GSR) ran into issues during their prototype seafloor nodule collector technology trial involving the connection between the umbilical and the collector. Before the incident happened, the trial had been progressing well, with the collector successfully traversing the seafloor and collecting nodules.

Importantly, GSR had prepared for multiple scenarios and the vehicle was successfully recovered within a few days and soon after was working again on the seafloor at 4200 m water depth. At the time, Kris van Nijen, Managing Director of GSR said: “We are taking a cautious, step-by-step approach to project development. We conduct these trials to better understand the challenges involved so we can continuously refine our technology. The prototype has functioned well, and learnings will be taken into the next phase of development.” For GSR, attention now turns to developing a full-scale system with riser pipe.

These recent demonstrations—both by TMC and GSR—represent a culmination of many hours of research and development work on dry land, stretching back years. Okeanus was involved very early on in the development of a collector concept for OceanfLORE, a joint venture between IHC and DEME Group. DEME group later founded GSR.

This work, almost a decade ago, had its roots tracing back to some early SOSI and ‘70s collector designs. The final design has evolved since those concept stage CAD drawings, but the hallmarks of the initial engineering principles applied remain, and with good reason.

Original concept drawings for GSR/DEME’s collector, over ten years ago. (Image credit: Okeanus/DEME)

At Okeanus, we believe that the goal when designing technology to reliably operate in harsh and often unpredictable waters is to, as per the fabled U.S. Navy “KISS” principle (Keep It Simple Stupid) decrees, avoid “overengineering” a solution. Understanding what you can and cannot control at depths found in the CCZ is paramount, and unnecessarily complicating a mining system in the interests of stretching yield is an obvious trap.

The most expediate and considered route to commercialization for deep-sea mining is one that promotes a greater transparency of in-situ testing, to both help abate environmental concerns and streamline monitoring and regulation. Some mining companies have, traditionally at least, been somewhat guarded about their proprietary technologies, but this will only anchor progress today. Clarity of information and cooperation are the key ingredients to meaningful collaboration now.

Operating in the deep ocean is challenging. The key, for an operator, is to manage any incidents that may occur and mitigate against a possible reoccurrence. Therefore, having the right launch and recovery assets and deck handling equipment to deploy these ultradeep-water systems—or indeed the ancillary assets such as an ROV to monitor its progress—is imperative.

Okeanus specializes in the design, development, and manufacturing of a wide variety of specialty multi-purpose winches, A-Frames, and Launch And Recovery Systems (LARS) for commercial Deepwater exploration. But we also recognize that, as is the case with pioneering deep-sea mining campaigns, for many applications a standard commercial-off-the-shelf product is simply not suitable or readily available. For such projects we partner with clients to engineer from scratch or manipulate existing proprietary designs to generate a purpose-built design ready for fabrication.

To find out more about Okeanus’ expanding portfolio of full-service fulfillment and turnkey design and fabrication services, visit: www.okeanus.com.

This feature appeared in Ocean News & Technology (ON&T) Magazine’s December 2022 edition, to read more about The Future of Ocean Technology access the magazine here.

255 Equity Blvd.

Houma, LA 70360, USA

+1 985.346.4666

11989-A FM 529

Houston, TX 77041, USA

+1 713.460.1400